Metal Melting Equipment

Which Metal Melting Equipment is best for you?

Here at Seba Developments, we offer a wide range of Metal Melting Equipment well suited to various needs.

Bench Top Metal Melters

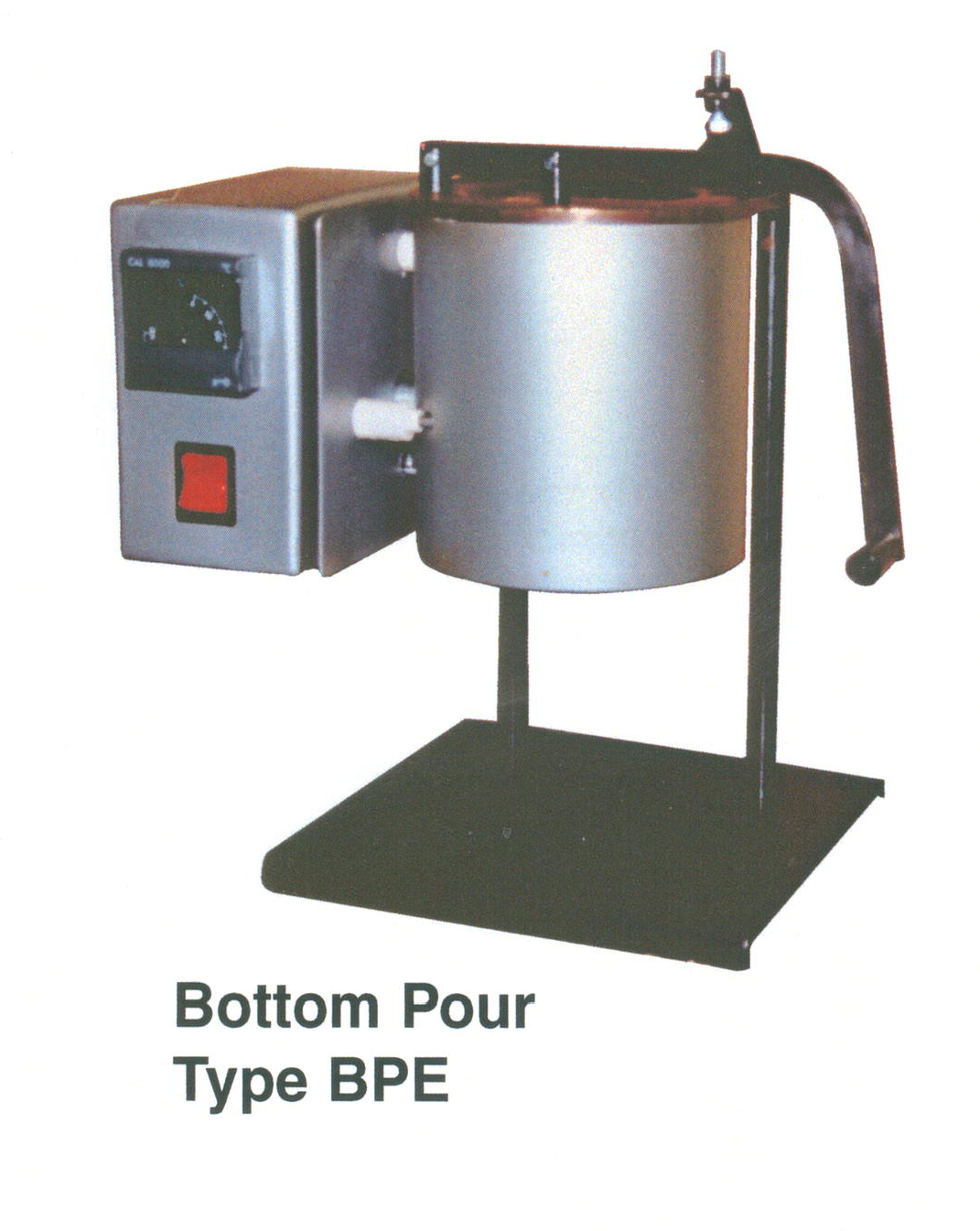

Our Bench Top Metal Melters are great for industrial and hobbyist users with shorter space or low volumes of product to heat. Due to their relatively small form, they can easily fit on a tabletop. Temperatures go up to 550 °C with a fully adjustable digital controller. Capacities range from 5Kg.Pb to 40Kg.Pb is standard and can come with a tilting lever or bottom pourer if required. Due to the nature of these melters, they are great for creating models, tinning or soldering (though we would recommend our HandiPot range for this.)

Our Bench Top Metal Melters are great for industrial and hobbyist users with shorter space or low volumes of product to heat. Due to their relatively small form, they can easily fit on a tabletop. Temperatures go up to 550 °C with a fully adjustable digital controller. Capacities range from 5Kg.Pb to 40Kg.Pb is standard and can come with a tilting lever or bottom pourer if required. Due to the nature of these melters, they are great for creating models, tinning or soldering (though we would recommend our HandiPot range for this.)

Large Capacity Metal Melters

Need to heat a lot of product at once? Our Large Capacity Melters might be precisely what you need. Similar in concept to our Bench Top Metal Melters but on a much larger scale. Capacities range from 5Kg.Pb up to 350Kg.Pb as standard. We can also go higher than this, but we would like to discuss your requirements before proceeding, so call or email us to get our custom design process. These melters are electrically heated, inert high, temperature blanket insulated with temperatures up to 500ºC. They are great for Tinning or casting, and some of our users even use them for creating ingots.

Need to heat a lot of product at once? Our Large Capacity Melters might be precisely what you need. Similar in concept to our Bench Top Metal Melters but on a much larger scale. Capacities range from 5Kg.Pb up to 350Kg.Pb as standard. We can also go higher than this, but we would like to discuss your requirements before proceeding, so call or email us to get our custom design process. These melters are electrically heated, inert high, temperature blanket insulated with temperatures up to 500ºC. They are great for Tinning or casting, and some of our users even use them for creating ingots.

Alloy Melting Tank

The Multi-Melter was initially designed for creating masks for protection for radiation therapy. It’s a versatile bench-top low-temperature (up to 200 C) alloy melting tank. It has 3 Tier heating level in the tank for flexibility and speed, as well as a sloping base for maximum alloy discharge. They come with a lockable valve to prevent accidental discharge. Our Multi-Melters are great for lining the inner pipes to avoid kinking and holding components in jigs for machining.

The Multi-Melter was initially designed for creating masks for protection for radiation therapy. It’s a versatile bench-top low-temperature (up to 200 C) alloy melting tank. It has 3 Tier heating level in the tank for flexibility and speed, as well as a sloping base for maximum alloy discharge. They come with a lockable valve to prevent accidental discharge. Our Multi-Melters are great for lining the inner pipes to avoid kinking and holding components in jigs for machining.

HandiPot Solder Pot

We manufacture round and square benchtop solder pots in various sizes and wattages—ideal for reliable control of solder temperature across multiple manufacturing environments. Typical uses include tinning the ends of wire leads, pre-tinning electrical parts, re-tinning soldering iron tips and dip soldering printed circuit boards.

We manufacture round and square benchtop solder pots in various sizes and wattages—ideal for reliable control of solder temperature across multiple manufacturing environments. Typical uses include tinning the ends of wire leads, pre-tinning electrical parts, re-tinning soldering iron tips and dip soldering printed circuit boards.

Custom Design

Not seeing someone that would work for you, or want to get some advice from our technical sales team? Give us a call at +44 (0) 1535 687799 or email to discuss anything about our ranges or to start designing your custom product.

Showing the single result